The Relevance of Calibration in Maximizing Your Galvanometer Scanner's Efficiency

The Relevance of Calibration in Maximizing Your Galvanometer Scanner's Efficiency

Blog Article

The Role of a Galvanometer Scanner in Improving Information Purchase Effectiveness

Galvanometer scanners function as crucial parts in the world of data procurement, especially due to their ability to accomplish specific and quick positioning of reflective components. This capability not only increases the scanning process but also enhances measurement precision through innovative comments devices. Industries varying from biomedical to producing increasingly depend on these gadgets for efficient information collection. Nevertheless, the ramifications of their integration expand beyond simple effectiveness; they welcome a closer exam of their operational devices and the future innovations that may additionally change data procurement techniques.

Understanding Galvanometer Scanners

Making use of specific electromagnetic concepts, galvanometer scanners serve as crucial tools in information acquisition systems, making it possible for the accurate dimension and recording of electric signals. These tools are developed to convert electric signals into mechanical motion, which can after that be imagined or videotaped. The essential attribute of a galvanometer scanner is its ability to react to variations in current, allowing it to identify minute modifications in electric signals with high level of sensitivity.

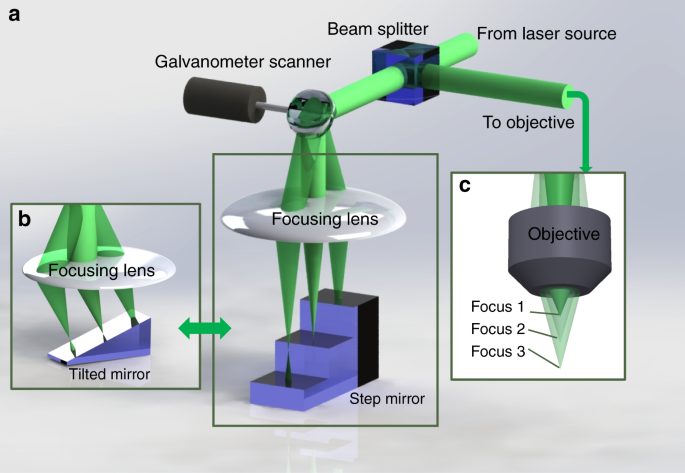

Galvanometer scanners are pivotal in a selection of applications, consisting of biomedical research study, optical scanning, and quality assurance processes in manufacturing. Their ability to provide trustworthy and rapid readings makes them suitable for environments that require high accuracy and fast reaction times. Additionally, the building of galvanometer scanners usually includes a light-weight coil put on hold in an electromagnetic field, enabling them to achieve high angular deflection with very little inertia.

The flexibility of galvanometer scanners enables assimilation into numerous information acquisition systems, enhancing the total efficiency of signal measurement. By making certain exact and rapid analyses, these devices dramatically add to the dependability of data evaluation, which is vital in both scientific research and industrial applications.

Mechanism of Operation

The operation of a galvanometer scanner depends on the interaction between electric currents and magnetic areas to produce mechanical motion. When an electrical present passes with the coil, it creates a magnetic area that communicates with the exterior magnetic area, resulting in torque that triggers the coil to rotate.

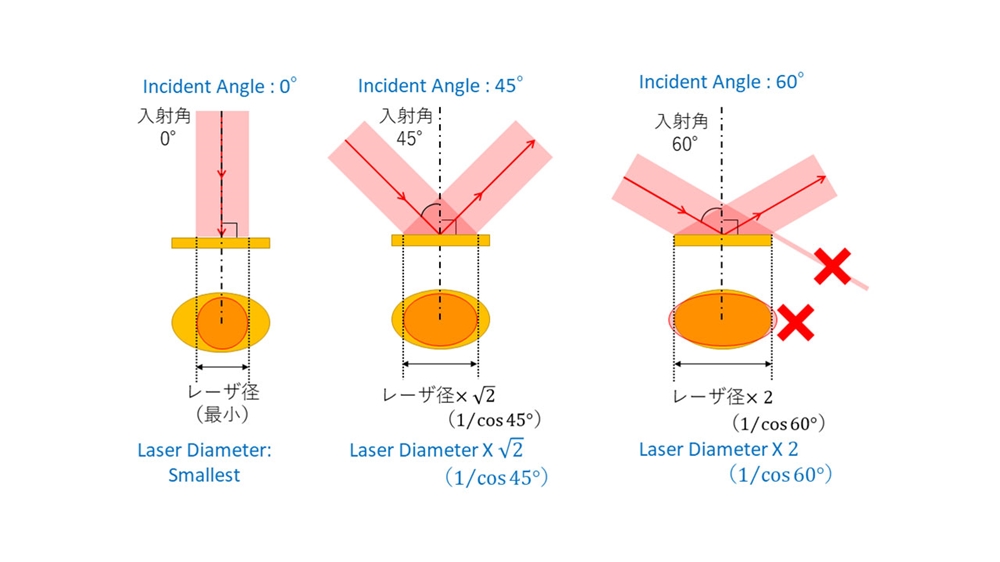

The input current's variation directly affects the angle of deflection, enabling the scanner to respond precisely to changes in the input signal. By adjusting the current's intensity and direction, the galvanometer scanner can achieve accurate and quick positioning of a reflective aspect, such as a mirror. This capability is vital in applications requiring specific positioning and scanning, as it assists in the controlled activity of other signals or light beams.

The feedback device incorporated within lots of galvanometer scanners further enhances their accuracy. Sensors keep track of the setting of the coil, providing real-time information that can be utilized to adjust the existing dynamically. This closed-loop control system guarantees that the scanner maintains precision throughout its functional range.

Applications in Various Industries

Galvanometer scanners find comprehensive applications throughout various markets because of their accuracy and fast feedback capacities. In the field of telecommunications, they are indispensable to laser beam of light guiding for optical networking, making it possible for high-speed data transmission. Clinical diagnostics additionally benefit significantly from galvanometer scanners, as they are utilized in laser-based see here imaging systems, such as Optical Coherence Tomography (OCT), providing high-resolution pictures for better medical diagnosis.

Additionally, in scientific research study, galvanometer scanners are essential for laser scanning microscopy, enabling researchers to catch detailed pictures of biological specimens and materials. They are additionally employed in metrology for high-precision measurements, guaranteeing conformity with stringent market requirements. On the whole, the versatility and efficiency of galvanometer scanners make them crucial across diverse industries, significantly adding to developments in technology and high quality assurance.

Benefits for Information Acquisition

In data procurement procedures, the consolidation of galvanometer scanners significantly improves dimension accuracy and speed. These gadgets make use of high-precision mirrors and fast angular activities to direct laser beams or light sources with impressive accuracy, which is critical for applications needing specific positioning and timing.

The versatility of galvanometer scanners permits smooth assimilation right into various data purchase systems, adjusting to specific requirements in fields such as biomedical imaging, materials testing, and environmental tracking. This adaptability not just improves the versatility of the equipment however likewise optimizes the total efficiency of data collection operations.

Furthermore, the portable layout of galvanometer scanners assists in easy installation and upkeep, further find more info adding to functional performance. Eventually, the benefits of utilizing galvanometer scanners in information purchase refines translate to far better high quality data, minimized functional prices, and boosted job turn-around times.

Future Trends and Innovations

Innovations in technology are poised to drive the development of galvanometer scanners, better improving their function in data purchase. Emerging technologies are likely to focus on boosting scanning speeds and enhancing accuracy, permitting a lot more effective information collection in applications varying from biomedical imaging to industrial automation.

Integration of expert system and artificial intelligence algorithms is anticipated to play an essential duty in optimizing scanner efficiency. These innovations can allow real-time modifications during the try these out scanning process, improving accuracy and lowering mistakes. Moreover, the consolidation of advanced products, such as lightweight composites, can result in the growth of more dexterous scanners with boosted responsiveness.

In addition, the fad toward miniaturization will likely result in small galvanometer systems, making them much more easily accessible for numerous applications, including portable tools. Improved connection with IoT integration can assist in smooth data transfer and remote surveillance, more enhancing data procurement procedures.

As the need for high-resolution imaging and rapid data handling continues to grow, galvanometer scanners will develop to satisfy these demands, placing themselves as essential devices in the pursuit for efficiency throughout multiple fields. The future promises a transformative trip for galvanometer modern technology, driven by advancement and precision.

Final Thought

In conclusion, galvanometer scanners substantially boost data procurement efficiency with their precise and rapid placing abilities. As sectors proceed to integrate these scanners into their systems, continuous advancements and fads are expected to more maximize their performance, solidifying their essential function in the evolution of information procurement modern technologies.

Galvanometer scanners serve as pivotal elements in the world of data procurement, particularly due to their capacity to achieve precise and fast positioning of reflective elements.Utilizing accurate electro-magnetic concepts, galvanometer scanners offer as essential devices in information procurement systems, enabling the exact dimension and recording of electric signals. Overall, the adaptability and efficiency of galvanometer scanners make them essential across varied fields, significantly contributing to advancements in innovation and high quality guarantee.

One of the key advantages of galvanometer scanners is their capability to accomplish high-speed information collection.In conclusion, galvanometer scanners significantly enhance information procurement efficiency with their accurate and fast placing abilities.

Report this page